Front end planning (FEP) is “the process of developing sufficient strategic information with which owners and contractors can address risk and decide to commit resources to maximize the chance for a successful project.” After researching this topic for the past three decades, including assessment of over $120 billion of projects, it is clear that the benefits of well-performed front end planning is the reduction of project costs; less project variability in terms of cost, schedule, and operating characteristics; and an increased chance of a project meeting its environmental and social goals. Front end planning is arguably the single most important process in the facility project life cycle. It creates strong early links between the business or mission need and the project’s strategy, scope, cost, and schedule, and maintains these links throughout the project life.

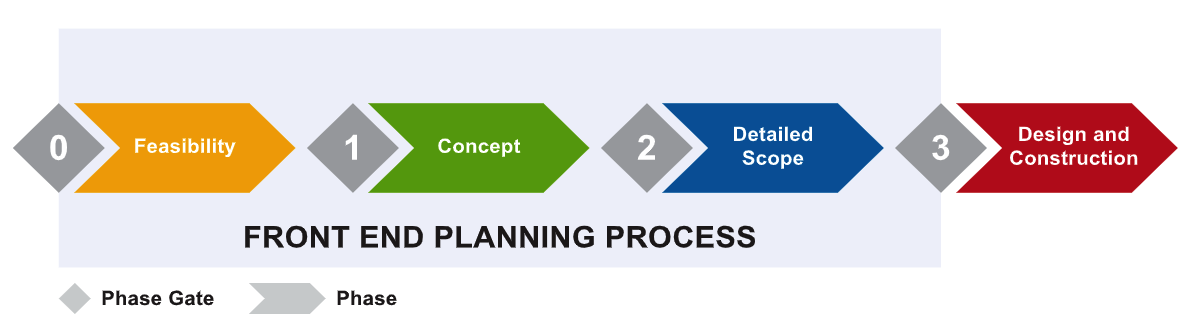

Other industry terms for front end planning include front end loading, pre-project planning, programming, schematic design, design development, sanctioning, and others. Because the research has, from the beginning, strongly suggested a direct relationship between project success and degree of front end planning, many organizations have classified it as one of their best practices. The figure below illustrates the three sub-phases of the front end planning within the larger context of the typical project life cycle. The diamonds in the diagram represent key decision gates that must be addressed before the project team can move on to subsequent phases. Of course, the organization wants to follow the process using best judgment while having enough agility to pursue opportunities. It comes down to adapting the process to the project at hand and the business drivers. Short-circuiting this process will almost always lead to project inefficiencies and problems.

Many companies have adopted a gated project delivery process in some form or variation. One of the main purposes of the gated delivery process is to help owners screen for the most worthwhile ventures and, once projects are chosen, to determine whether the correct progress is being made during their front end planning. Another key purpose is to ensure that the team is pursuing the right project for the business situation. Yet another is to guide a consistent approach toward front end planning. Of course, some have pushed back against using a standard FEP process, claiming it is too bureaucratic, or that it stifles innovation, or that there is a new, better way. No research data has ever shown that another process (i.e., agile, OS 2.0 or others) works effectively to front end plan a capital facility. There is plenty of evidence that shows that a lack of process and discipline during this part of the project can lead to disaster.

Most facility owners have more potential projects than they have the resources to execute. Using the front end planning process will minimize the effort and expense needed to identify the feasibility of a project. At each gate, the process requires the project team to prepare and submit for approval a pre-defined set of process deliverables before proceeding to the next stage of the process. Culling projects that do not meet the needs of the organization is a good consequence of this evaluation process. Evaluations are repeated for each gate and will generally be focused on the following activities:

Phase Gate 0: Initiation of the project

Phase Gate 1: Verification of feasibility

Phase Gate 2: Identification and selection of alternative ways to achieve business or mission objectives

Phase Gate 3: Development of a scope of work that has a high degree of predictability in terms of cost, schedule, and quality.

If the project does not align or meet the business, mission, or regulatory requirements at any of the gates, it can be cancelled quickly and the organization can focus on the next potential project.

Typical FEP activities and products may include the following:

- Options analysis

- Scope definition and boundaries

- Life-cycle cost analysis

- Cost and schedule estimate

- Site investigation

- Environmental analysis

- Process design basis

- Initial equipment design

- Space planning, including room data sheets and

stacking diagrams - Site layout

- Project execution approach, including project control plan

- Procurement plan

- Architectural renderings

- Appropriation submittal package.

Front end planning is not just a technical process; it is a best practice that helps people work better together with more alignment. Team alignment is recognized as an important activity during successful front end planning. Alignment is defined as the condition under which appropriate project participants work within acceptable tolerances to develop and meet a uniformly defined and understood set of project objectives.

In summary, FEP is a best management practice that can be measured and improved. It is generally the best path to gain a successful project outcome.